Description

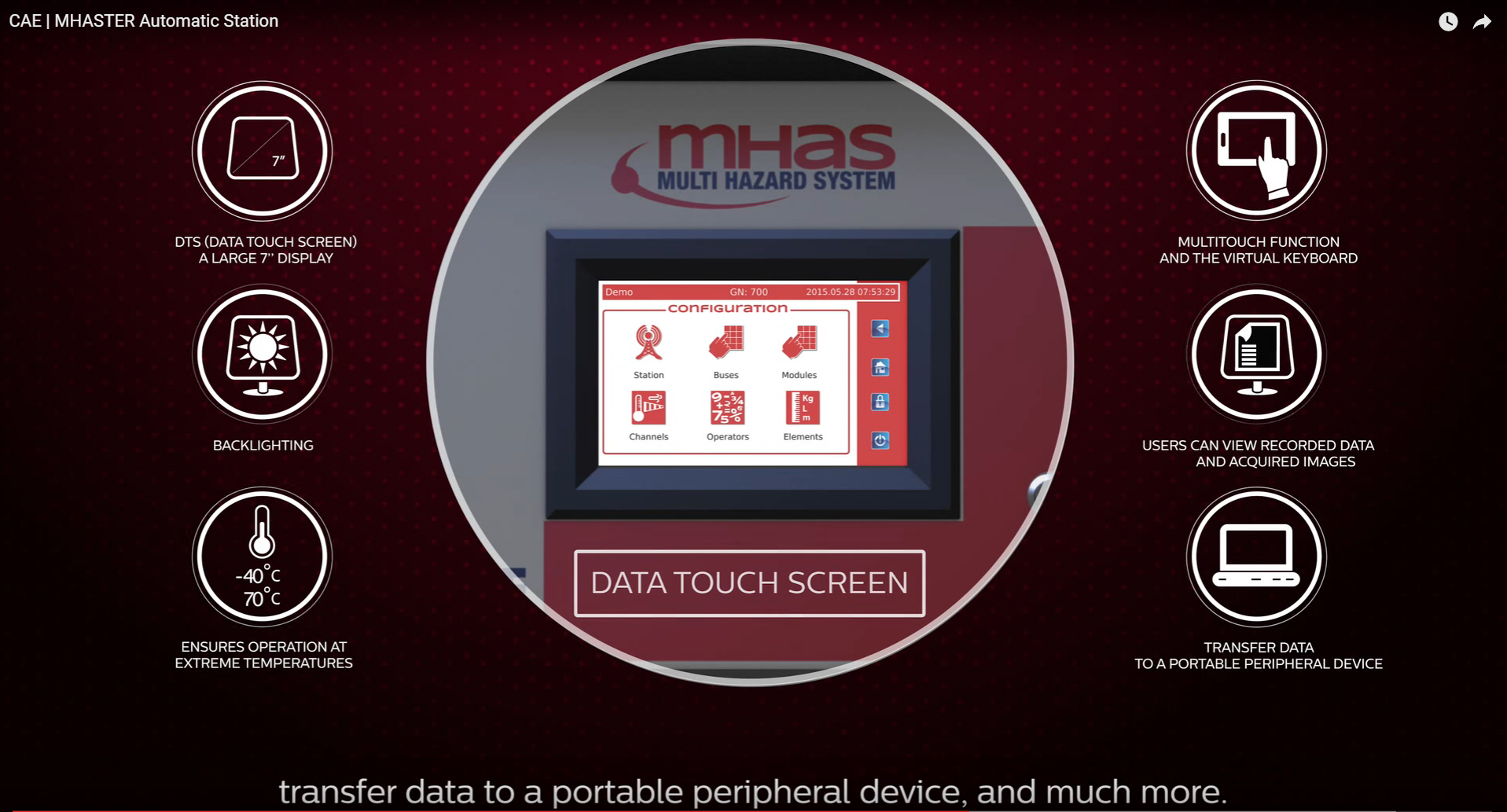

The Mhaster is the datalogger to which they referred all the management tasks of the equipment in the field. A powerful hardware has been built based on embedded Linux operating system to best achieve all these activities, while ensuring high flexibility and user friendly graphical interface.

The high computing capacity made available by Mhaster allows a complete multitasking, i.e. operation allows users to perform multiple tasks simultaneously. Communication activities and the elaboration by the datalogger happen, in normal conditions, in a few seconds. This allows the optimization of the operation, with a consequent limitation in energy consumption.

The high computing capacity of the data logger also makes possible the compression and encryption of data by mean of standard procedures, or the development of applications by the Client or third parties, e.g. implementation of computational algorithms which may activate alarms locally or remotely when certain events happen.

Features

Technology

- - the attention to detail, starting with the design phase;

- - encoded, tracked and certified production processes;

- - the use of high quality materials;

- - the experience and training of production engineers.

- - redundant elements, which make sure that, if an element breaks, the product sends an alert while operating normally, giving time to intervene with the replacement without losing any data;

- - diagnostic sensors of various types, such as the ones for the verification of:

- o the correct inclination of the product,

- o the quality of the acquired measurement,

- o the value of the voltage input,

- o the status of inputs and outputs,

- o the conditions of the internal temperature,

- o the reliability of the RF link between all devices,

- o etc.